Development and introduced technologies

The origins of the district heating supply of Salaspils region can be traced back to 1970, when the construction of the first boiler house was started in Salaspils, where sulfur-containing fuel oil was used as fuel. The capacity of the boiler house was not enough for the needs of a rapidly growing city, thus in 1977 the 10.5-kilometer-long main heating line Riga TEC-2 - Salaspils was built. Taking into account large heat energy losses in the heating main, in 1995 a decision was made to abandon the main heating main and modernize the local heat source.

Salaspils city municipal company "Salaspils Siltums" was founded in 1996.

The company started rapidly growing in 2010 when an ambitious process of modernization and process optimization was launched:

2019

ISO

In December, Salaspils Siltums introduced the LVS EN ISO 50001: 2018 energy management system, an amended version of LVS EN ISO 50001: 2012, which the company initially implemented in 2016.

2019

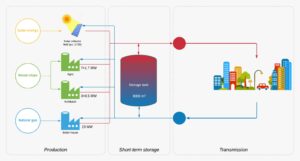

Heat storage tank and solar field

The project “The transition to the use of renewable energy resources of the heat source at 31A Miera Street, Salaspils” was completed. Starting from September, the new boiler house, heat storage tank and solar collector field started operating. The project is implemented thanks to the support of the European Union Cohesion Fund.

2018

Projects

Project “The transition to the use of renewable energy resources of the heat source at 31A Miera Street, Salaspils” was launched. It was planned to build a 8000 m3 heat storage tank, a new wood chip boiler house with a total capacity of 3 MW, equipped with flue gas condenser and to install field with 1720 solar collectors.

2017

86 solar panels

86 solar panels were installed on the roof of the administration building with a total capacity of 25 kW, which allows to fully provide the administration building with the necessary electricity during the summer period and partially supply electricity to the rest of the property. One of this project’s main benefits is significant emission savings – 436.5 tons of CO2 per year.

2016

Reduced CO2

As a result of the implemented modernization measures, the company reduced CO2 emissions by 80% in 2016 compared to 2011, while the heat tariff from 2010 to 2016 was reduced by 23%.

2012/2013

Data reading system

An electronic data reading system was introduced, enabling an operative control of heat energy production, consumption and losses in heating mains.

2012

Saulkalne gas water heating boiler

A spare gas water heating boiler was installed in Saulkalne boiler house.

2012

New biofuel boiler

A new biofuel (wood chips) boiler with a capacity of 7 MW has been put into operation.

2011 - 2014

Heating main in Salaspils

In Salaspils, obsolete heating mains were replaced with industrially insulated pipes.

2010

Heating main in Saulkalne

In Saulkalne, the heating main was completely replaced by industrially insulated pipes.

2010 - 2017

Three new gas boilers

Three new gas water heating boilers were installed in the Salaspils boiler house, replacing the old and obsolete equipment.